Litavimo stotelė su skaitmeniniu LED ekranu

Litavimo stotelė su skaitmeniniu LED ekranu

Kodas: YT-824615229 €Šią prekę turime sandėlyje.Profesionalių įrankių linija.

Prekės ženklasYATO-

Product description

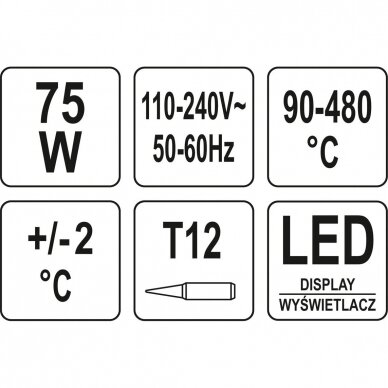

YT-82461 soldering station with digital LED display, temperature control and temperature calibration function has been designed to work with a tip with a built-in heater. T12 tips are a combination of a resistance wire embedded in ceramics, a temperature sensor and a high-quality soldering tip. The integrated construction of the tip enables express heating and very fast temperature stabilization. The Yato station, as one of the few on the market, has an additional function that extends the life of the heater and temperature sensor, which significantly improves the economy of the tip with an integrated structure. The soldering iron allows for quick tip replacement, it is very pleasant to the touch and has one of the lowest distance between the handle grip and the soldering point, which is very useful during precise works.power: 75W

temperature range: 90 - 480 ° C

temperature accuracy: + - 2 ° C

temperature stabilization

temperature calibration

on-off button on the front

The digital display with red LED backlight informs us about:

set and real temperature of the tip

temperature calibration function settings

Soldering iron:

heater operating voltage: up to 24V

tip type: T12

quick tip change

heater and temperature sensor built into the tip

slim handle made of high-quality plastic

Small distance between the handle grip and the soldering point: the tip protrudes only 45 mm

high temperature resistant flexible cable

cable length: 1.05 m

weight of the butt with the tip + cable: about 65 g

the set includes a T12-ILS tip - for precision works, a tip with a diameter of only 0.15 mm

The YT-82461 soldering station heats up to the operating temperature of 350 ° C in about 20 seconds, while it heats up to about 85% of the set point value, i.e. in this case to about 300 ° C in 7 seconds.T12 GROOVES: ADVANTAGES AND DISADVANTAGES AND EFFECT OF POWER MANAGEMENT ON THEIR LIFE

One of the greatest advantages of an integrated tip design is the elimination of the air resistance problem between the soldering tip and the temperature sensor. The temperature sensor in the T12 tips is connected in series with the heater * and is placed in the solder tip as close to its tip as possible. Thus, any temperature change, e.g. when soldering large components, is almost immediately read by the temperature stabilization function, which will adjust the power of the device in real time to maintain the set setpoint. **

Another advantage appreciated by many users is the speed of changing the soldering tip, and even the possibility of replacing it without having to wait for the tip to cool down. To do this, use a heat-resistant material to grab the hot tip and slide it out of the soldering iron.

The series connection of the temperature sensor and the heater undoubtedly has many advantages, but also has the disadvantage of reducing the life of the sensor itself. Yato YT-82461 soldering station as one of the few on the market has a special function limiting the negative impact of such a solution:

In the last phase of the tip reheating, the station software gradually reduces the heater power before it reaches 100% of the setting. For example, when the temperature is set to 350 ° C, the station will work at full power to about 85% of the setpoint value, and gradually reduce this power for the last 15%. This type of control reduces the negative impact of power jumps both for the station itself and for the elements of the arrowhead. Intelligent power management also has a positive effect on the precise operation of the temperature stabilization function.

OTHER FUNCTIONS

The temperature stabilization function allows to maintain the set temperature of the tip in various conditions of heat demand for the proper soldering connection. The tip, depending on the size of the soldered element and the solder pad, gives off more or less heat, and the device, using the built-in tip temperature sensor, reads its real value on an ongoing basis and compares it to the set one, then, depending on the needs, it increases or decreases the power consumption to maintain the set temperature.

The temperature calibration function allows you to calibrate the built-in temperature sensor. Depending on the quality, size and degree of wear of the tip, a demanding user can calibrate the sensor with the help of a temperature measuring device. Correct reading not only has a positive effect on temperature stabilization, but helps an experienced user to avoid the error of overheating the connection in PCBs.

ATTENTION* The temperature sensor in the T12 tips is connected in series with the resistance wire / heater, and communication with the control system is via the heater power cables. Usually, in this type of constructions, a special control system cuts the power supply to the heater for less than a millisecond, reads the temperature of the tip tip and adjusts the power consumption parameters on an ongoing basis, depending on the needs. It is a cyclical process, imperceptible during normal operation, and its effect is the stabilization of the tip temperature.

** For comparison, the temperature stabilization in devices with a flask design with a heater and a tip slid over it is delayed by the influence of air resistance. The air in the free space between the tip and the heater must also heat up or cool down, which further extends the reaction of the temperature sensor built into the heater. Stabilization, especially in older constructions, where the temperature sensor was built into the center of the heating element, worked slowly. Modern flasks, such as those in the YT-82456, YT-82458 and YT-82459 devices, have new generation heaters with a special shape and with a temperature sensor located at its end. Thus, the tip adheres well to the heater, and the influence of air resistance on the stabilization function is kept to a minimum.

Parameters

Power [W]: 75

Dimensions [mm]: 140 x 58 x 30

Warm-up time [s]: 20 s to 350 ° C

Max temperature of the tip [° C]: 480